WellHead Vacuum Compressor

Designed to increase production of a low pressure natural gas well by removing the wellhead pressure and allow the flow of liquids and gas.

Introduction

The Emmecom VCU series wellhead vacuum package is specifically designed to boost well head gas flow by reducing the flowing wellhead pressure. The liquid ring vacuum pump design offers the deep vacuum capability down to -90 Kpa (100 mbar absolute) and are ideally suited for “unconventional gas” applications such as enhancing the gas flow rate of low pressure wells, coal seam gas & land fill gas.

The VCU series have a heavy duty structure that allows a greater differential pressure generation of up to 3 bar, and able to generate a discharge pressure of positive 2.5 bar depending on operating conditions. The package allows a negative pressure to be applied to the wells and can:

- increase gas production for low pressure gas wells

- remove low pressure gas to aid in oil production

Applications

LOW PRESSURE GAS WELLS

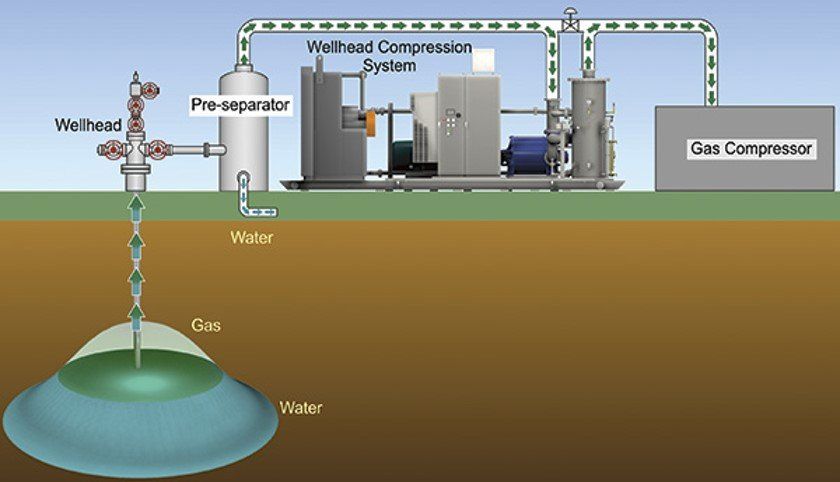

The wellhead vacuum unit could be placed on a single wellhead or on a gathering line to reduce the back pressure on the well bore, aiding low pressure wells to flow better and increase gas production rates.

OIL WELLS WITH GAS VAPOURS

The wellhead vacuum unit could be placed on a single wellhead or on a gathering line to remove the gas vapours within the well, reducing the pressure caused by the gas vapours on the well. The results is an increase in oil production.

The diagram below shows how the system could be set up.

Standard Systems

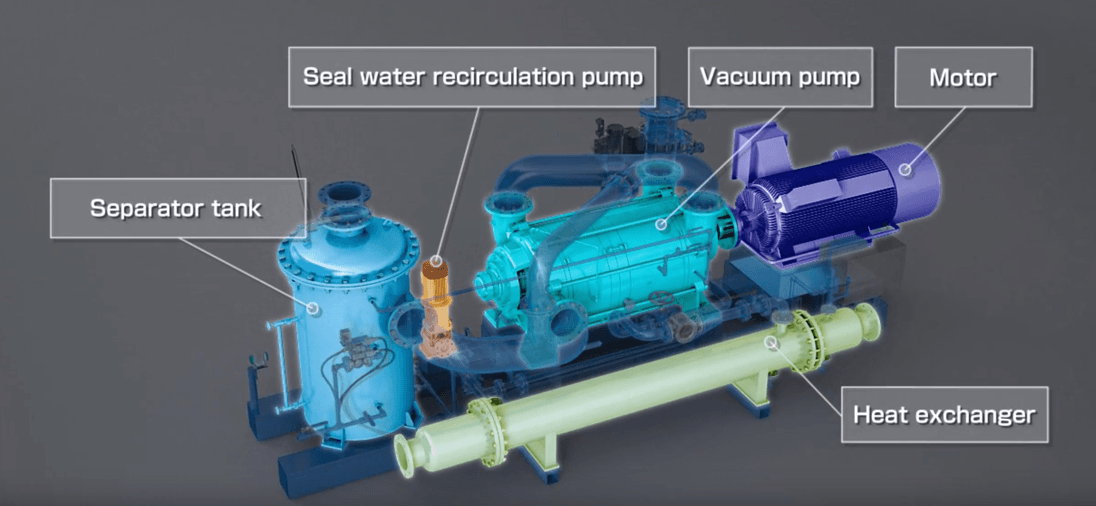

A standard Vacuum Compressor Unit (VCU) consist mainly of the Liquid Ring Vacuum Pump (LRVP) - single, double or multi unit in parallel arrangement depending on required flowrate, a seperator (knock-out tank), a heat exchanger and associated pipeworks and controls.

We provide a complete plug and play system complying to International and Australian standards.

Benefits of a Liquid Ring Vacuum Pump Type Wellhead Vacuum Compressor

LOW OPERATING TEMPERATURE – Suitable & safe for flammable & explosive gases

VERY LOW NOISE & QUIET OPERATIONG – No suction silencer needed

NO METAL – METAL CONTACT – Low vibration, low noise and able to handle dust & coal fines

HIGHER COMPRESSION RATIO – Able to generate up to 6 bar compression

STABLE & RELIABLE – Low speed operation results in low noise & vibration, increased run life

NO LUBRICATION NEEDED – Liquid sealing & cooling, no metal to metal contact

LOW MAINTENANCE – No metal to metal contact, water as seal, double mech seal, between bearing design, all of which contributes to the lowest maintenance in its class (vacuum & gas compression)