Oilless Vacuum Pumps

GEV's Oilless Vacuum Pump range provides a low maintenance, no contamination vacuum operation.

Introduction

GENERAL EUROPE VACUUM a Company born from the twenty years experience of a group of skilled and capable people, who along these years engineered, manufactured and installed “General” plant fit for pharmaceutical and chemicals industries and consequently availing themselves of the research carried out during these years, has finally decided to develop and manufacture VACUUM PUMPS.

GENERAL EUROPE VACUUM engineers and manufactures a comprehensive range of oilless & lubricated vanes vacuum pumps with capacities from 3 to 800 m3/hr in addition to ” custom-made ” process vacuum plants.

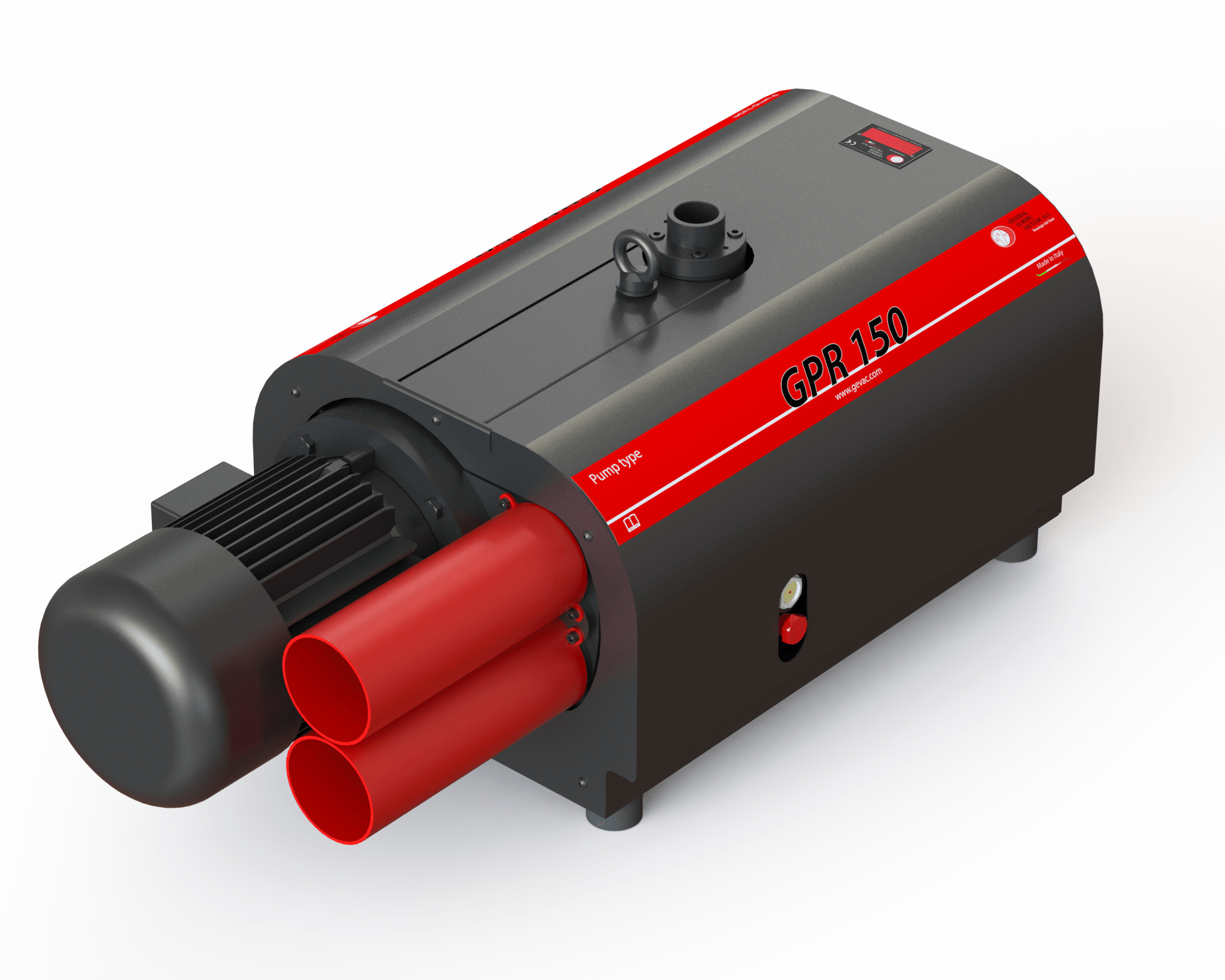

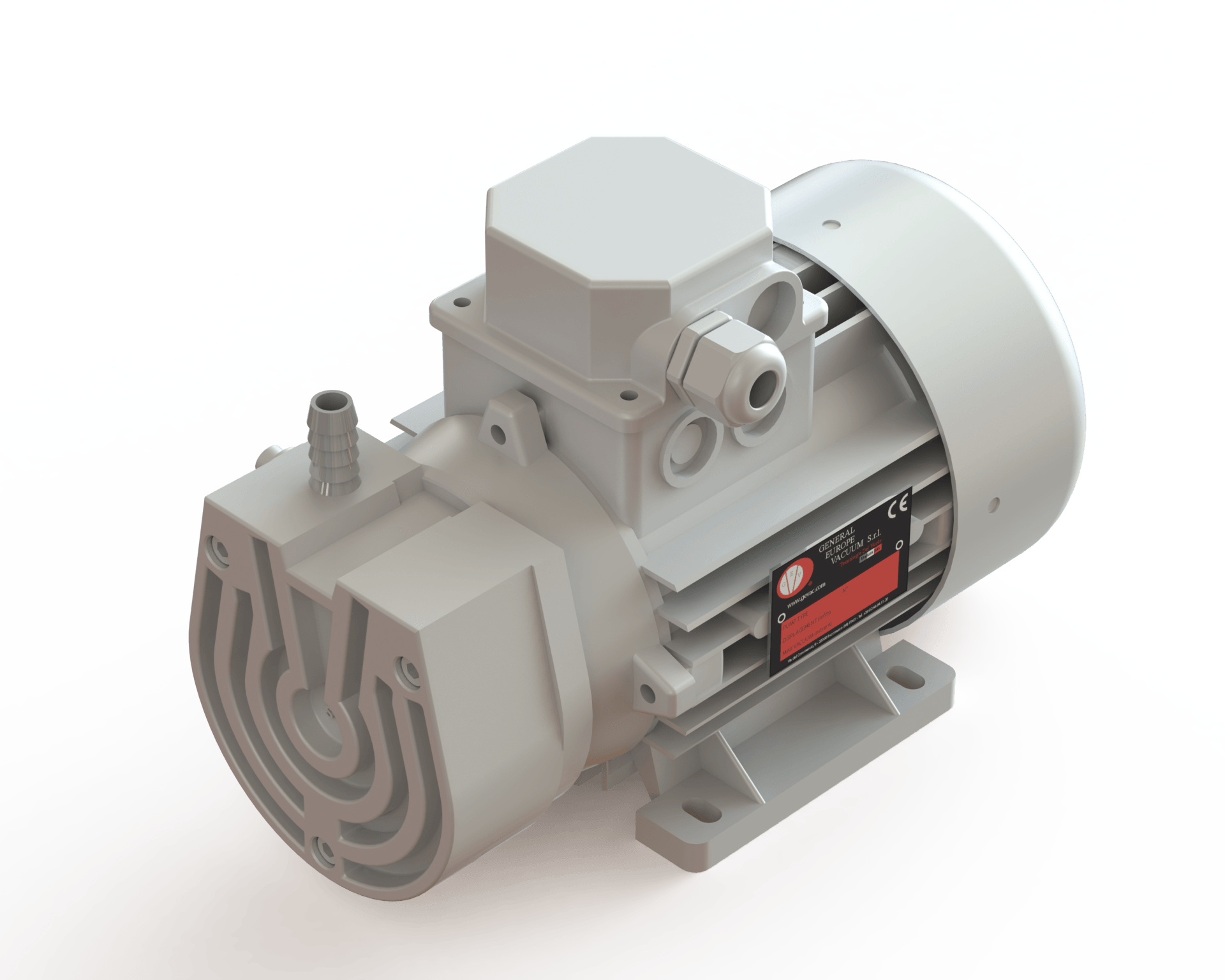

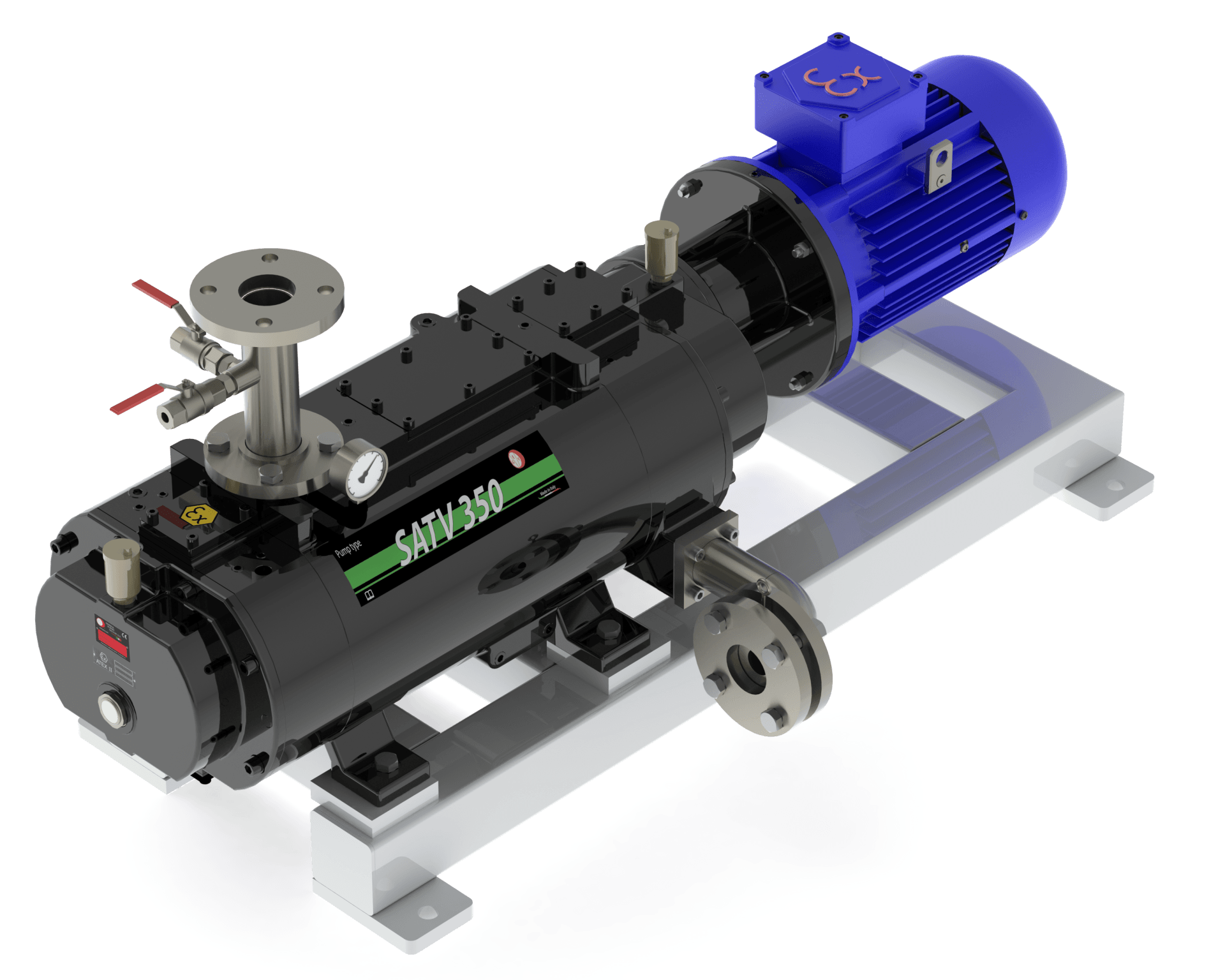

GEV's Oilless Vacuum Pump range includes a Claw Type Vacuum Pump, an Oil Free Rotary Vane Vacuum pump, and a Dray Screw Vacuum Pump.

Applications

- Beverage Industry

- Atex

- Bricks Manufacturing

- Chemical & Pharmaceuticals

- Composite

- Electronics

- Environmental Technology

- Lifting/Handling

- Medical & Hospital

- Packaging

- Degassing

- Drying

- Forming, Pressing and Laminating

- Water Treatment

- Textile Industry

The 3 different types of oilless vacuum pumps in GEV's ranges are as follow.

GEV Oilless Vacuum Pump